Top Suppliers Types Of Powder Coating - Titanium Parts – Lead

Top Suppliers Types Of Powder Coating - Titanium Parts – Lead Detail:

Titanium Parts

We are very experienced in the customized production of machined titanium parts. We provide super quality of machined titanium parts, which are designed to meet our customer’s target.

We maintain proactive communication with our customers to assure that we fully understand our customers’ requirements and produce parts with the desired characteristics in the most cost effective manner.

Advantage of Machined Titanium Parts

Strength and lightweight: As strong as most common steels with less than 40% of the counterpart’s weight

Corrosion resistance: Almost as resistant to chemical attack as platinum. One of best candidates for seawater and chemical handling components

Cosmetic appeal: Titanium cosmetic and technical appeal even outperforms the precious metals especially in the consumer marketplace

What are the advantages of titanium, and which titanium are popular ?

Titanium is a new metal, it has many significant advantages over other metals.

1. High strength: Titanium alloy density is generally 4.51g / cubic centimeter, only 60% of steel, pure titanium density is close to the density of ordinary steel, so titanium alloy specific strength is much larger than other metals.

2. High heat strength: Titanium alloy operating temperature can be up to 500 ℃, while aluminum alloy has to at 200 ℃.

3. Good corrosion resistance: Titanium has good corrosion resistance to alkali, acid, salt etc.

4. Good Low temperature performance: Titanium can still maintain its mechanical properties at low temperature and ultra-low temperature.

Machining titanium has several advantages over other materials. Titanium machined parts are known for their high strength and weight; it is also ductile, corrosion resistant against salt and water, and has a high melting point, making it the perfect option for many industries and applications.

Some of the most popular titanium alloys follow:

Gr1-4, Gr5, Gr9 etc,

There are two common casting titanium alloys: Titanium Grade 2 and Titanium Grade 5. Please see below for detailed characteristics, applications etc.

Grade 2 titanium is highly resistant to chemical environments including oxidising, alkaline, organic acids and compounds, aqueous salt solutions and hot gases. In seawater, Grade 2 is resistant to corrosion at temperatures up to 315°C, rendering it ideal for a variety of marine uses

Titanium Grade 5 is the most commonly used Titanium worldwide. Aerospace, medical, marine and chemical processing industries and oil field services

What Application Do Titanium Mainly Used For ?

Titanium is often used in: aircraft, automotive and motorcycle, chemical equipment, medical equipment, hiking equipment etc.

Wuxi Lead Precision Machinery manufactures brass parts using many different processes: machining, milling, turning, drilling, laser cutting, EDM, stamping, sheet metal, casting, forging, etc.

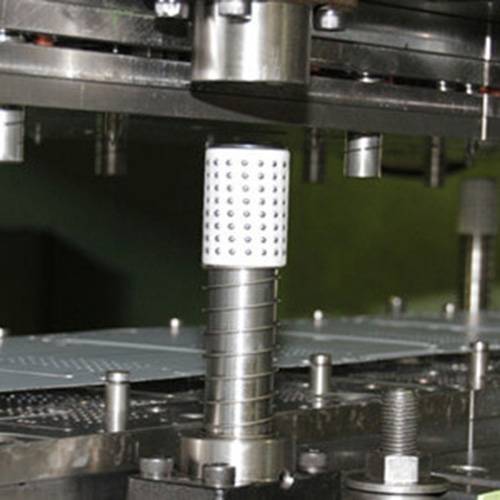

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Top Suppliers Types Of Powder Coating - Titanium Parts – Lead , The product will supply to all over the world, such as: Italy, Macedonia, Sri Lanka, We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ‘customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.