New Delivery for Precision Medical Machining - Plastic Parts – Lead

New Delivery for Precision Medical Machining - Plastic Parts – Lead Detail:

If you have plastic parts need machined or molded, we are one of the most capable and affordable sources, and we can get the job done right.

Which plastic materials we can do and what are the materials properties ?

Comparing metal material, plastic material has cheap cost, light weight, good corrosion resistance and good heat-insulating performance advantages.

1. PTFE: also called Teflon, it has good high temperature resistance, good corrosion resistance, high lubrication, nonhazardous and electric insulativity advantage.

2. PC(Polycarbonate): is a strong thermoplastic resin, it has good mechanicalproperty, high transparency and freedom of dyeing and Good aging-resisting and heating-resisting properties.

3. Nylon: has a high mechanical strength, high softening point, good heat resistance, low friction coefficient, good wear resistance, good electrical insulation Self-extinguishing, non-toxic, odorless and good weather resistance. Besides, after adding glassfiber, the tensile strength can be increased about 2 times.

4. ABS: is the largest and most widely used polymer. It has good impact resistance, heat resistance, low temperature resistance, chemical resistance and electrical properties, and easy to machining.

5. Acrylic: also called PMMA, has a good transparency, chemical stability and weather resistance, easy to dye, easy to processing, beautiful appearance and other properties.

Which applications are plastic materials mainly used for ?

Because of cheap cost and light weight, plastic materials are mainly used for construction, automotive, industry, medical, transportation, electronic and other applications.

Machining quality parts from UHMW. We can machine intricate parts on our CNC Swiss machines and CNC turning centers.

Ultra-High Molecular Weight polyethylene (UHMW) is a high-density plastic, ideal for screw machine parts that require extremely high resistance to wear and abrasion. It has the highest impact strength of any thermoplastic and is highly resistant to most corrosive materials. UHMW is self-lubricating and performs well in extraordinarily low temperatures, but begins to soften in higher temperatures. Unlike nylon, it has a very low moisture absorption rate, making it suitable for use in wet environments.

Ultem has a machining cost factor of 0.7 when compared to steel 12L14.

Industries & Applications

● Bushings

● Bearings

● Sprockets

Wuxi Lead Precision Machinery manufactures brass parts using many different processes: machining, milling, turning, drilling, laser cutting, EDM, stamping, sheet metal, casting, forging, etc.

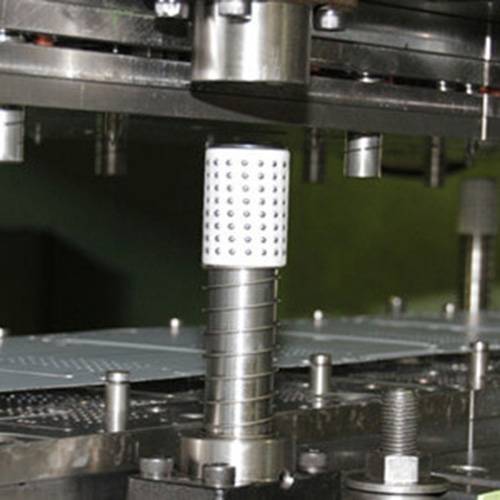

Product detail pictures:

Related Product Guide:

"Quality to start with, Honesty as base, Sincere company and mutual profit" is our idea, as a way to build constantly and pursue the excellence for New Delivery for Precision Medical Machining - Plastic Parts – Lead , The product will supply to all over the world, such as: Lithuania, Czech Republic, Sacramento, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!