Factory selling Cnc Lathe Service - CNC Milling – Lead

Factory selling Cnc Lathe Service - CNC Milling – Lead Detail:

Product Description

CNC Milling has several advantages over other manufacturing processes. It is cost effective for short runs. Complex shapes and high dimensional tolerances are possible. Smooth finishes can be achieved. CNC milling can produce almost any 2D or 3D shape provided that the rotating cutting tools can reach the material to be removed. Examples of parts include engine components, mold tooling, complex mechanisms, enclosures, etc.

Computer Numeric Controlled (CNC) Milling is a machining process primarily used in Oil and Gas Industries. CNC Milling uses a rotating cutting tool similar to drilling, the difference being that there is a cutter which moves along different axes creating multiple shapes that can include holes and slots. It is the common form of Computer Numerical Control Machining as it performs the functions of both drilling and turning machines. It is the easiest way of getting precision drilling for all types of quality materials to produce products for your business.

Difference Between CNC Milling and CNC Turning

CNC Milling and CNC Turning allow users to create patterns and add detail to metals that are impossible to do by hand. CNC Milling uses commands, codes programmed into the computer and set to run. The mill then drills and turns along axes to cut materials to dimensions entered into the computer. Computer programming allows machines to make precise cuts, users can manually override the CNC Machines to slow or speed up the process.

In contrast, CNC Turning uses computer-controlled machines to create a different final product. The process uses a single-point cutting tool that inserts parallel to the material to cut. The material is rotated at changing speeds and the tool cutting traverses to create cylindrical cuts with exact measurements. It is used to create circular or tubular shares from larger material pieces. It is an automated process and speeds can be adjustments for greater accuracy rather than turning a lathe by hand.

Meet Our Machines

- eight Okuma MA-40HA Horizontal Machining Centers (HMC)

- four Fadal 4020 Vertical Machining Centers (VMC)

- one Okuman Genos M460-VE VMC equipped with chip removal systems and automatic tool changers

Meet Our Capabilities

Shapes: As your required

Size range: 2-1000mm diameter

Material: Aluminum, Steel, Stainless Steel, Titanium, Brass, etc

Tolerance: +/-0.005mm

OEM/ODM are welcomed.

Samples are available before mass production

Additional services: CNC Machining, CNC Turning, Metal Stamping, Sheet Metal, Finishes, Materials, etc

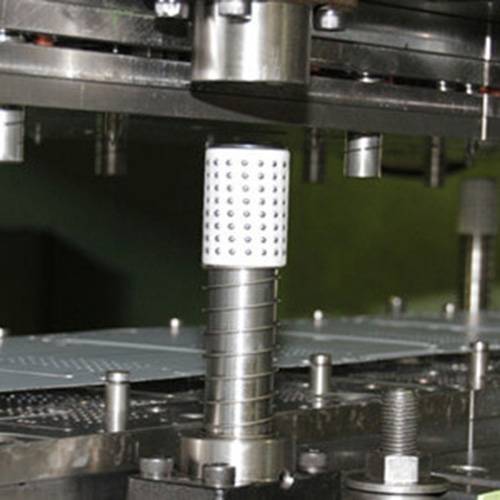

Product detail pictures:

Related Product Guide:

Our advantages are lower prices,dynamic sales team,specialized QC,strong factories,high quality products and services for Factory selling Cnc Lathe Service - CNC Milling – Lead , The product will supply to all over the world, such as: Gambia, Sao Paulo, Mumbai, Our products are widely sold to Europe, USA, Russia, UK, France, Australia, Middle East, South America, Africa, and Southeast Asia, etc. Our products are highly recognized by our customers from all around the world. And our company is committed to continually improving effectiveness of our management system to maximize customer satisfaction. We sincerely hope to make progress with our customers and create a win-win future together. Welcome to join us for business!

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!