Chinese wholesale Cheap Cnc Service - CNC Machining – Lead

Chinese wholesale Cheap Cnc Service - CNC Machining – Lead Detail:

Product Description

As a 15 years experience custom CNC Machining Parts fabricator, we can design and manufacture complex parts end-to-end using multiple tools in a single cell. We also run a comprehensive jigging system around the 4th axis so multiple numbers of parts can be machined along several planes in one setting.

CNC machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

Short for “computer numerical control,” the CNC process runs in contrast to — and thereby supersedes — the limitations of manual control, where live operators are needed to prompt and guide the commands of machining tools via levers, buttons and wheels. To the onlooker, a CNC system might resemble a regular set of computer components, but the software programs and consoles employed in CNC machining distinguish it from all other forms of computation.

CNC Machine Shop Services

Standard CNC machining processes may include the following machining techniques:

Milling — bringing a rotating cutting tool into contact with a stationary workpiece

Turning — rotating a workpiece to contact a cutting tool; lathes are common

Drilling — bringing a rotating cutting tool into contact with a workpiece to create a hole

Boring — removing material to form a precise inner cavity within a workpiece

Broaching — removing material with a series of shallow cuts

Sawing — cutting a narrow slit in a workpiece using a saw blade

Benefits of CNC Machining Services

Material: Aluminum, Steel, Stainless steel, Titanium, brass, copper, fiberglass, plastic, etc

Finishes: Anodized, Polished, Sand Blast, Powder coated, Electroplated, Nitriding, etc

Equipment: 3 axis cnc machined, 4 axis cnc machined, Common machines, drilling machine, CNC engraving machine, laser engraving machines, etc

Tight tolerance:0.005-0.01mm

Roughness value: less than Ra0.2

Additional services:CNC Machining, CNC Turning, Metal Stamping, Sheet Metal, Finishes, Materials,, etc

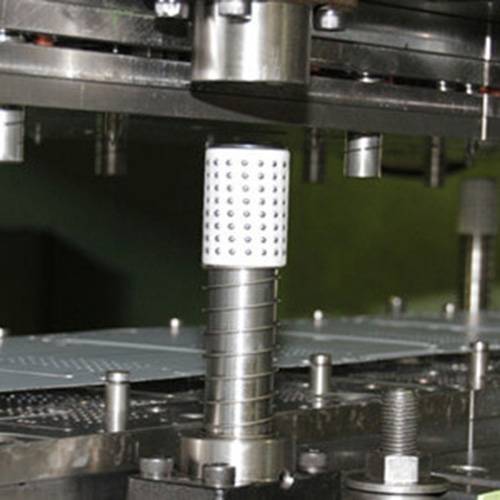

Product detail pictures:

Related Product Guide:

Together with the "Client-Oriented" enterprise philosophy, a arduous good quality control technique, sophisticated producing equipment and a sturdy R&D staff, we generally offer superior quality merchandise, superb solutions and aggressive rates for Chinese wholesale Cheap Cnc Service - CNC Machining – Lead , The product will supply to all over the world, such as: Swiss, Munich, Morocco, Although continuous opportunity, we have now now developed serious a friendly relationship with many oversea merchants, such as ones through Virginia. We securely assume that the merchandise regarding t shirt printer machine is often good through a great number of having its good quality and also cost.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.