In the mold manufacturing process, the forming portion of the mold often needs to be surface polished. Mastering the polishing technology can improve the quality and service life of the mold and thus improve the quality of the product. This article will introduce the working principle and process of mold polishing.

1. Mold polishing method and working principle

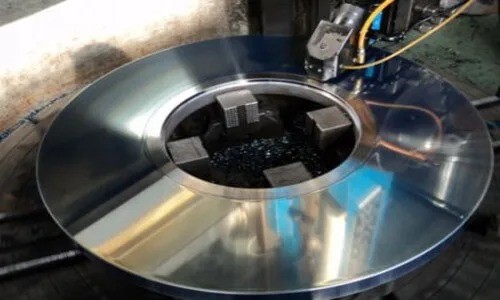

Mold polishing usually uses oil stone strips, wool wheels, sandpaper, etc., so that the surface of the material is plastically deformed and the convex portion of the surface of the workpiece is removed to obtain a smooth surface, which is generally performed by hand. The method of super-fine grinding and polishing is required for high surface quality. The super-fine grinding and polishing is made of a special grinding tool. In the polishing liquid containing abrasive, it is pressed against the machined surface to perform high-speed rotary motion. Polishing can achieve a surface roughness of Ra0.008μm.

2. The polishing process

(1) rough polish

Fine machining, EDM, grinding, etc. can be polished with a rotating surface polisher with a rotational speed of 35 000 to 40 000 r/min. Then there is a manual oil stone grinding, strip of oil stone plus kerosene as a lubricant or coolant. The order of use is 180#→240#→320#→400#→600#→800#→1 000#.

(2) Semi-fine polishing

Semi-finishing mainly uses sandpaper and kerosene. The number of sandpaper is in order:

400#→600#→800#→1000#→1200#→1500#. In fact, #1500 sandpaper only uses mold steel suitable for hardening (above 52HRC), and is not suitable for pre-hardened steel, because it may cause damage to the surface of pre-hardened steel and cannot achieve the desired polishing effect.

(3) Fine polishing

Fine polishing mainly uses diamond abrasive paste. If grinding with a polishing cloth wheel to mix diamond abrasive powder or abrasive paste, the usual grinding order is 9 μm (1 800 #) → 6 μm (3 000 #) → 3 μm (8 000 #). The 9 μm diamond paste and polishing cloth wheel can be used to remove the hair marks from the 1 200# and 1 50 0# sandpaper. The polishing is then carried out with a felt and a diamond paste in the order of 1 μm (14 000 #) → 1/2 μm (60 000 #) → 1/4 μm (100 000 #).

(4) Polished working environment

The polishing process should be carried out separately at two working locations, that is, the rough grinding processing location and the fine polishing processing location are separated, and care should be taken to clean the sand particles remaining on the surface of the workpiece in the previous process.

Generally, after rough polishing with oil stone to 1200# sandpaper, the workpiece needs to be polished to clean without dust, ensuring that no dust particles in the air adhere to the mold surface. Accuracy requirements above 1 μm (including 1 μm) can be performed in a clean polishing chamber. For more precise polishing, it must be in an absolutely clean space, as dust, smoke, dandruff and water droplets can scrap high-precision polished surfaces.

After the polishing process is completed, the surface of the workpiece should be protected from dust. When the polishing process is stopped, all abrasives and lubricants should be carefully removed to ensure that the surface of the workpiece is clean, and then a layer of mold anti-rust coating should be sprayed on the surface of the workpiece.

Post time: Jan-10-2021