Cnc Machining Aluminum Parts Factory – CNC Turning – Lead

Cnc Machining Aluminum Parts Factory – CNC Turning – Lead Detail:

Product Detail

1.all-round 360 production line cutting group stop workflow, enabling automatic tube feeding, automatic feed, automatic cutting, automatic transmission operation.

2.Using KASRY Nesting programming system as a major programming tool, the software programming platform AUTOCAD basic, simple, graphical and intuitive, feature-rich, it can greatly improve operational efficiency.

3.High-end three-dimensional flexible robotic cutting applications, to achieve bevel cutting function, the pipe and the torch using the servo positioning function .

Application

Can cut carbon steel, stainless steel, copper, aluminum and other pipes and profiles, such as: the tube, pipe, oval pipe, rectangular pipe, H-beam, I-beam, angle, channel, etc. The device is widely used in various kind of pipes profile processing field, shipbuilding industry, network structure, steel, marine engineering, oil pipelines and other industries.

CNC Turning

CNC turning produces parts by “turning” rod material and feeding a cutting tool into the turning material. On a lathe the material to be cut rotates while a cutter is fed into the rotating workpiece. The cutter can be fed at a variety of angles and many tool shapes can be used.

CNC Turning is an intricate and detailed method of creating custom parts and components using a lathe. Computer Numerical Control (CNC) turning is a highly skilled, Precision Engineering process.

What parts need CNC Turning?

There is no question that CNC Milling and CNC Turning are very different processes that will in most cases end up with entirely different results. CNC Centres are ideal for short-run volumes and especially prototypes and parts that are below 2.5” while the turning centre can be able to work on parts that are over the 2.5” OD, they will need to be checked individually and depending on the volume of the parts that are being produced, it can have an upward impact on the price of production. Also, if the part is less than 1.25” OD, turning might not be the option for producing that part. However, it is important to note that the biggest factor that determines if the piece can be produced by CNC Turning is the volume. The higher the volume the less suitable the part is suitable to be produced by turning.

Meet Our Machines

Okuma Twin Spindle Lathes

Mazak single spindle quick turn CNC lathe

Meet Our Capabilities

Tolerance: Roundness and concentricity accuracy can be reached to +/-0.005mm

Surface roughness can be reached to Ra0.4

Size range: Diameter of raw material round bars from 1mm to 300m

Material: Aluminum, Steel, Stainless steel, Titanium, brass, etc

OEM/ODM are welcomed

Samples are available before mass production

Additional services:CNC Machining, CNC Turning, Metal Stamping, Sheet Metal, Finishes, Materials,, etc

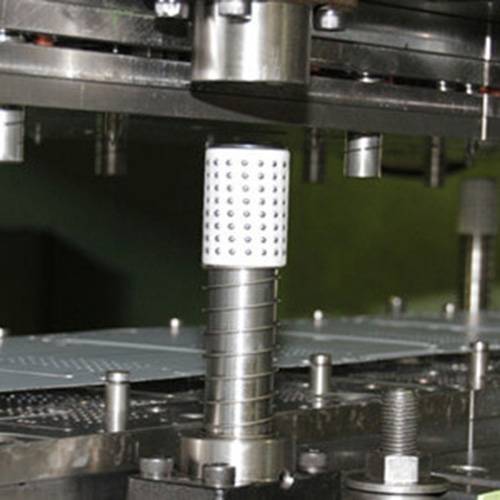

Product detail pictures:

Related Product Guide:

We are going to make every single effort for being excellent and excellent, and accelerate our ways for standing while in the rank of international top-grade and high-tech enterprises for Cnc Machining Aluminum Parts Factory – CNC Turning – Lead , The product will supply to all over the world, such as: Egypt, Houston, Denmark, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality products and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.